— Published on 03 Sep 2024

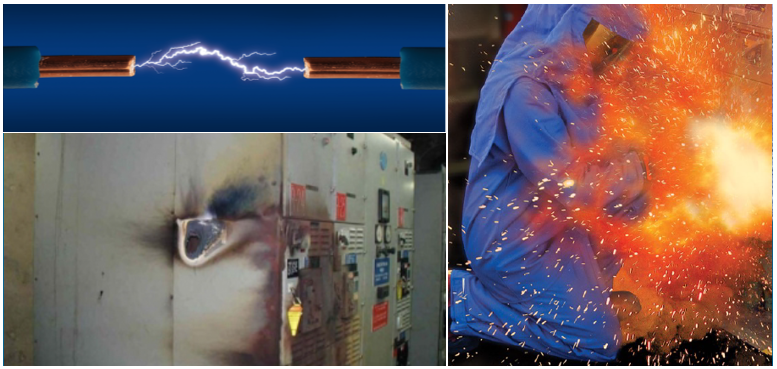

One of the leading causes of fatal and non-fatal electrical injuries are contacts with exposed wiring, or other electrical components during installation, maintenance, and repair works, that results in arc flash event. Primary injuries include electrical shock, thermal burns, or a combination of both.

In the simplest terms, arc flash is the energy release that occurs during an electrical fault when current flows through the air between two live conductors, causing a short circuit.

In a residential setting, an arc flash usually produces little more than a brief flash of light before extinguishing itself harmlessly.

However, voltages and currents tend to be significantly higher in an industrial setting, so electrical faults typically release far more energy. An industrial arc flash occurrences routinely produces a powerful explosion marked by high heat, toxic fumes, blinding light, deafening noise and massive pressure waves.

The main cause is usually an accidental short circuit in the electrical phases. Other causes can be attributed to:

According to Article 1001 of the National Fire Protection Association's NFPA 70E, arc flashes are prone to happen in instances where electrical equipment features exposed components or when individuals are engaging with enclosed equipment. An accidental contact with energized electrical parts can also initiate the arc flash and arc blast.

After de-energizing equipment and performing the necessary lockout/tagout steps, workers should treat the equipment as if it is still energized until proven otherwise. Verifying the absence of voltage is essential for laying a solid groundwork for an electrical safety program.

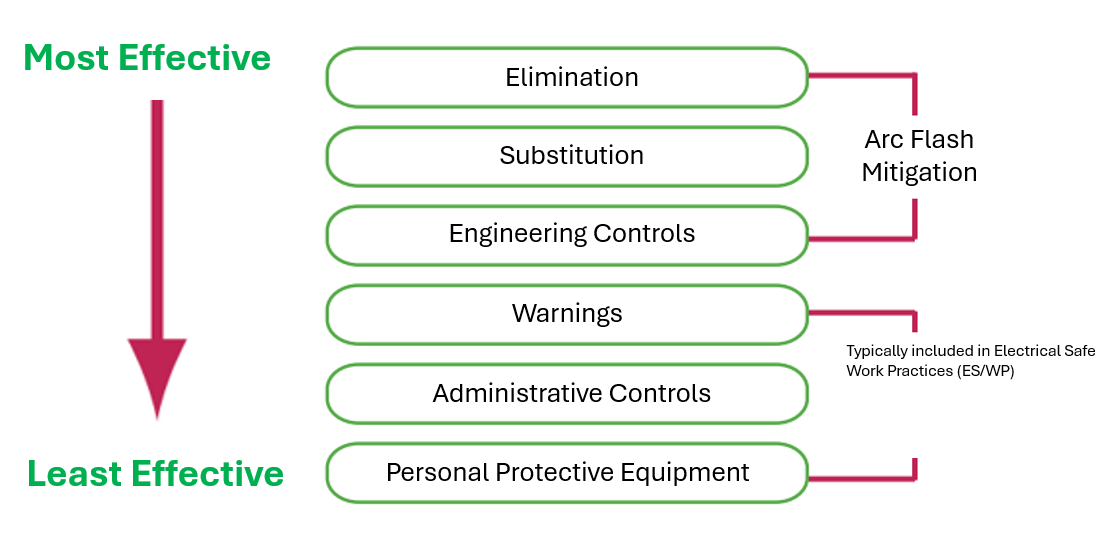

Reference from ANSI Z10-2012 Safety Standards, Occupational Health and Safety Management Systems.

The Occupational Health and Safety Management Systems - ANSI Z10-2012 Safety Standards2 released a hierarchy of arc flash mitigation controls, as shown. Among the six types of mitigation control methods, "Elimination" takes precedence, which essentially involves disconnecting the circuit from its source and confirming the absence of voltage.

Traditionally, ensuring equipment de-energization involves employing a portable hand-held voltage test instrument. However, the latest edition of NFPA 70E introduces an alternative option: the use of a suitably rated permanently mounted test device to confirm the absence of voltage in conductors or circuit parts at work sites.

Permanently mounted test devices known as Absence of Voltage Testers (AVTs) are specifically designed for this purpose. The standards and requirements for AVTs are detailed in UL1436 standard3, as specified in NFPA 70E 120.5 (7) Exception 1.

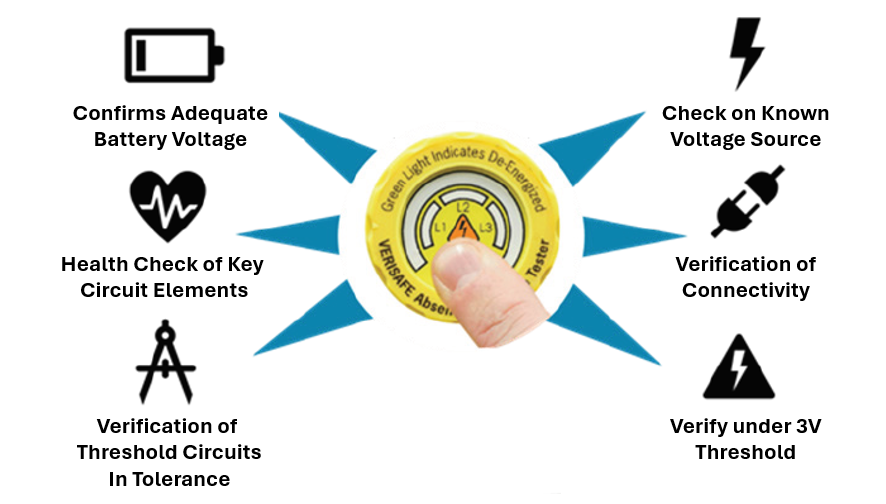

Panduit VeriSafe Absence of Voltage Tester (AVT) is the first absence of voltage tester listed to UL1436 standards, designed specifically to verify the absence of voltage in electrical enclosures.

Installed in the enclosure, Panduit VeriSafe AVT has the following features:

In conclusion, workers have developed confidence over decades in using portable testing instruments, and transitioning to the innovative approach of testing voltage absence with a device installed at the door will require an adjustment period.

As time progresses, workers will also develop confidence in the protection provided by the Verisafe AVT installed at the door, as it verifies voltage absence with the simple push of a button.

As time progresses, workers will also develop confidence in the protection provided by the Verisafe AVT installed at the door, as it verifies voltage absence with the simple push of a button.

Ultimately, the VeriSafe AVT plays a crucial role in ensuring the absence of voltage before workers access potentially hazardous electrical equipment. Its implementation not only enhances safety and efficiency but also complements existing lockout/tagout programs, further safeguarding workers in their daily tasks.

Visit http://www.panduit.com/verisafe for more information.

Reference:

Large Paragraph Text Used As A Subheading

Pellentesque non magna eget ex lobortis finibus. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam nec arcu non eros hendrerit viverra a vitae libero. Etiam et ultricies nulla. Donec euismod lectus magna, eu dignissim mauris hendrerit vulputate.

| Time | Place | Details |

|---|---|---|

| 10:00 am - 10:55 am | Expo Hall | Meet and greet in the lobby outside the Expo Hall before the General Assembly. |

| 11:00 am - 11:55 am | Rm 314 | Expert Track: TOP 10 WAYS TO MAKE A DIFFERENCE IN THE INDUSTRY | John Dough, CFO Marketizingly |

| 11:00 am - 11:55 am | Rm 159 | Social Track: MODERN NETWORKING | Hosted by: SponsorName |

Pellentesque non magna eget ex lobortis finibus. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam nec arcu non eros hendrerit viverra a vitae libero. Etiam et ultricies nulla. Donec euismod lectus magna, eu dignissim mauris hendrerit vulputate.